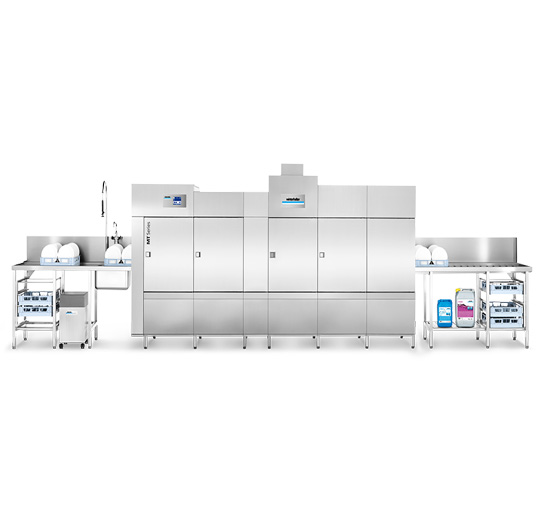

Description

The MTR is designed for the highest hygiene standards. With your machine architecture. Your hygiene and cleaning concept. Your special programmes and equipment details. It therefore meets all the requirements of the DIN standard.

Touch screen with self-explanatory pictograms. Intuitive programme selection. Doors that can be opened 180°. Open the unit effortlessly with just one finger. The well conceived details make operation of the MTR simple, safe and convenient.

The MTR warewashing system is extremely efficient. It ensures cleanliness and hygiene of the highest standard. At all times. Even with large loads of dishes.

With integrated economy functions: thanks to innovative technology in the rinse zone, water consumption is reduced to a minimum in the MTR. This also significantly reduces the consumption of energy and washing chemicals. Overall, that means lower operating costs. And greater cost-efficiency.

Intelligent use of energy: the MTR can be fitted with integrated »Energy« exhaust air heat recovery as an option. This uses the energy from the warm exhaust air to pre-heat the cold inlet water. This reduces energy consumption considerably and lowers operating costs.

An innovative feature of the MTF: the pre-wash, main wash and rinsing zones only operate when they are activated and required by items enerting the relative areas. This conserves resources and lowers your operating costs. Because water, power, detergent and rinse aid are used efficiently and economically.

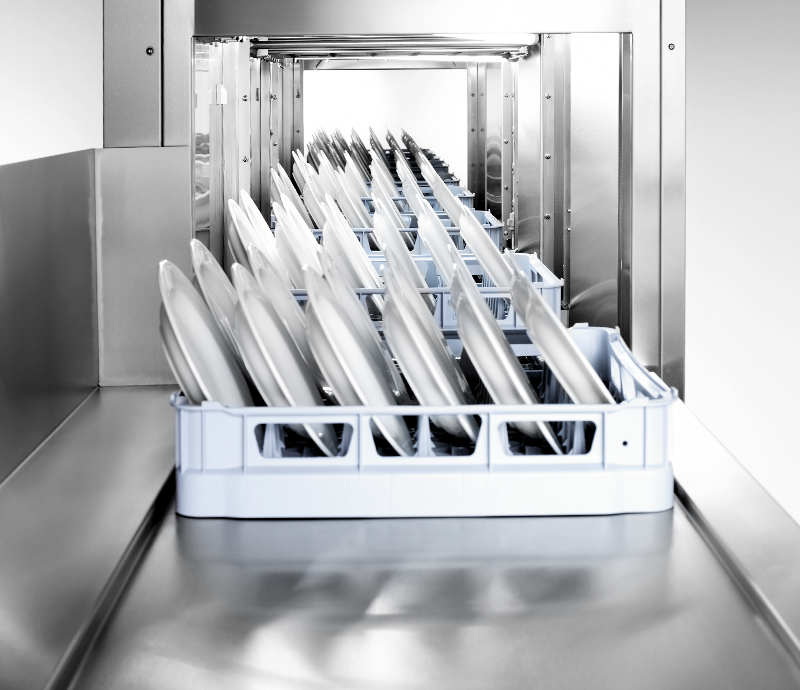

A special drive system makes it possible: the racks are transported through the individual zones of the MTR at a continuous speed. As a result, the wash items are in constant and steady contact with the water. For perfectly clean wash results.

The cleaner the wash water, the better the wash result. That’s why the MTR comes with an efficient wash water filtration system. Large dirt particles are caught in the individual zones by removable strainers. Mediamats then filter out the finest particles, such as coffee grounds. A pump inlet filter protects the pump from mechanical damage. As a result, the wash water remains clean at all times.

At the end of a working day: The MTR has a guided self-cleaning programme, to ensure the machine works perfectly for many years. Fully automatic cleaning of the interior of the machine is started using the touch screen. Rotating jets in the cabinet roof automatically clean the interior with fresh water. User-friendly pictograms on the display then guide you through the subsequent manual cleaning stages. The drain pump takes any residual water out of the machine and prevents deposits or odours.

Behind the conveyor warewashers of the MT Series there is a carefully thought-out concept for perfect hygiene and convenient cleaning. The interior of the machine is smooth and has no joints. The tank is deep-drawn. All this means: there are no hiding places or concealed corners in the interior in which dirt can accumulate or deposits can form. A hygiene door that opens 180° allows ergonomic access for cleaning the interior of the machine. In conjunction with the integrated self-cleaning programme, cleaning work is reduced to a minimum.

In addition to »Energy« exhaust air heat recovery, the even more efficient »ClimatePlus« heat pump is also available as an additional energy saving option for the MTR: this not only draws on the thermal energy from inside the machine to heat the tank and rinse water – it also uses the heat from the air in the room. This saves up to 16 kWh per operating hour. This reduces energy consumption considerably and lowers operating costs.

Note: Fluorinated greenhouse gases contained in a hermetically sealed device; refrigerant R134a, 2.19 kg, 3.1 tonnes of CO2 equivalent; greenhouse gas potential 1430.

The touch screen on the MTR is more than an operating panel: it is a language-neutral communication and control platform that is intuitive to use. Optical and acoustic signals not only provide information about the machine status, they also indicate any errors that occur. The optional external water treatment system can also be monitored. Upon entering their PIN, chefs and service technicians are able to enter a secure area in which operational and hygiene-related data can be accessed.